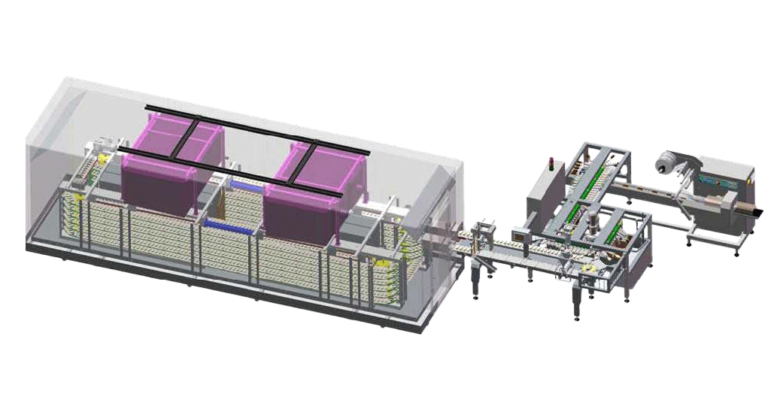

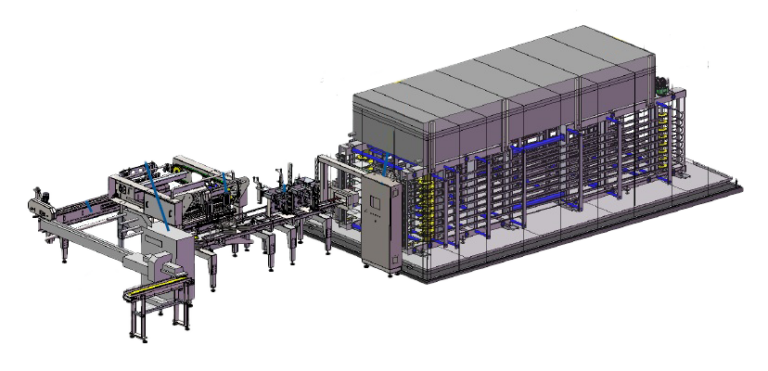

ST tunnels are designed and built according to the individual needs of each customer in order to optimize performance.

Technical specifications:

- One or two evaporators optimizes the refrigeration system and guarantees perfect ventilation inside the room.

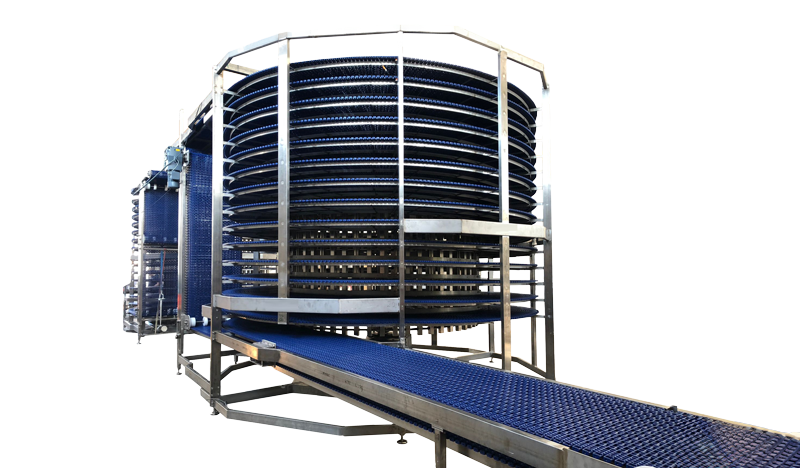

- One or two spirals, to guarantee the hardening time required for each product

- One or two compressors, manufactured by BITZER, with a wide range of gas options

- Movement via central drum which moves the belt, already tensioned by a gearmotor, when it turns

- Loading and unloading conveyors separated from the main structure of the spyral, to avoid thermal stress on the main spiral of the tunnel

- Modulating belt in certified plastic material, suitable for the type of treatment to be carried out, allows direct contact with loose and packaged foods;

- Low friction coefficient, high resistance to wear and traction ensure greater reliability and durability;

- All mobile surfaces and other profiles in contact with the belt are made of high density molecular polyethylene;

- The joint hinges, designed for the passage of detergents, guarantee levels of hygiene higher than standard ones;

- The surfaces of the belt are non-stick to allow perfect detachment of the product and residues during cleaning;

- The design is developed to eliminate / reduce the marking of the treated products.

The spiral structure is made of stainless steel with particular techniques to guarantee maximum sanitation during washing.

The chambers can be supplied with different degrees of insulation and with particular technical specifications depending on the operating temperature and installation conditions.

Control panel that allows the adjustment of the belt speed, ventilation and refrigeration system parameters.