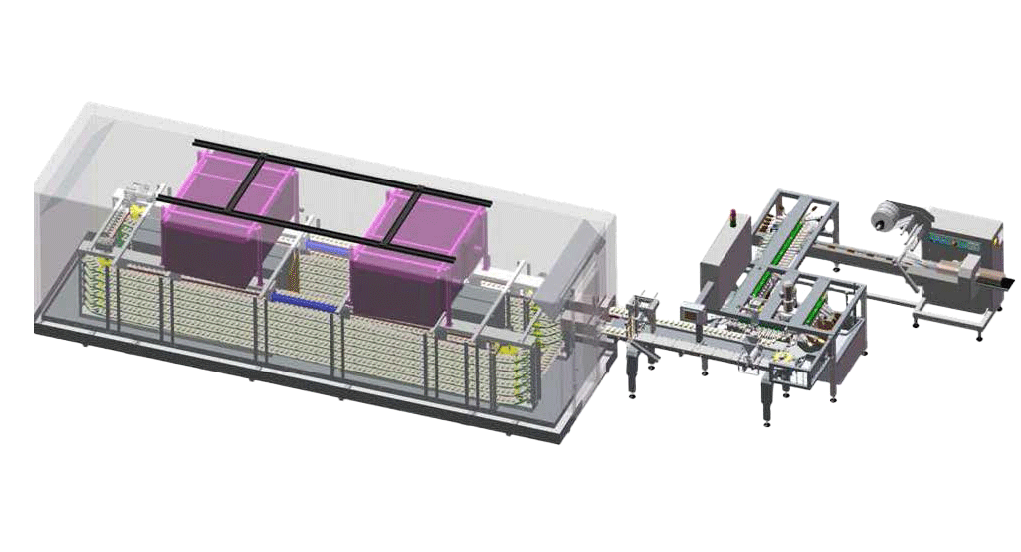

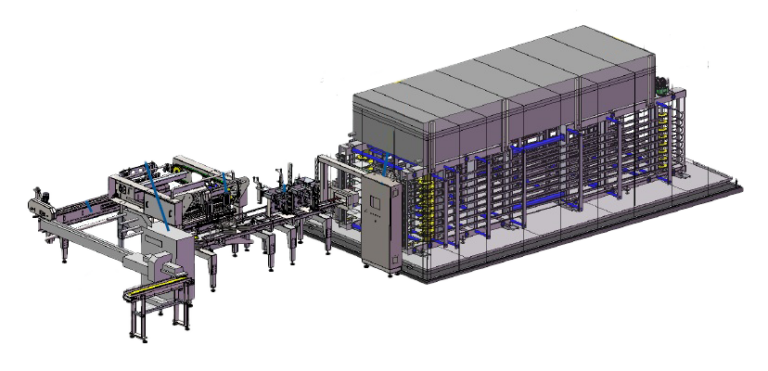

- isothermal box made in sandwich pannels of high density injected polyurethane, thickness 125 mm.

- n. 1 inspection door with safety handle inside, internal electrical light fittings, safety switch

- water resistant inside floor is covered by stainless steel AISI 304, thickness 1,5 mm, fully welded

- Inner mechanical robust structure, built completely in stainless steel.

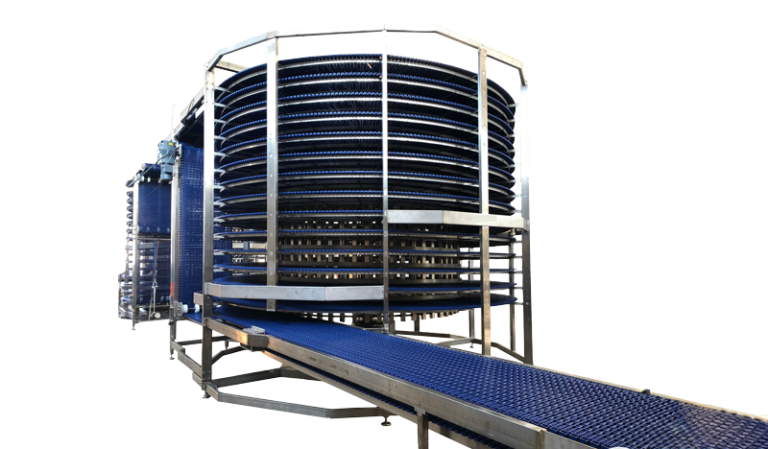

- central pneumatic tension station for the automatic compensation of chain’s dilatation. Precise tension adjustment for long chain life. Automatic tension disconnection when machine out of use.

- chain tensioning system for precise and equal chain extension during chain life

- water tight ball bearings, enclosed in support suitable for very low temperatures

- stainless steel lubrication-free chain (chain pitch 50,8 mm), carrying the trays. Lubrication free chain ensures the highest hygiene standard of production. The chain is driven by motorreducer assembly. Electronic control and synchronisation via frequency converter

- adjustable safety brakes and overload control to stop the chain whenever the stress limit is exceeded

- EVAPORATOR with high speed fans for the air circulation, all mounted inside the box