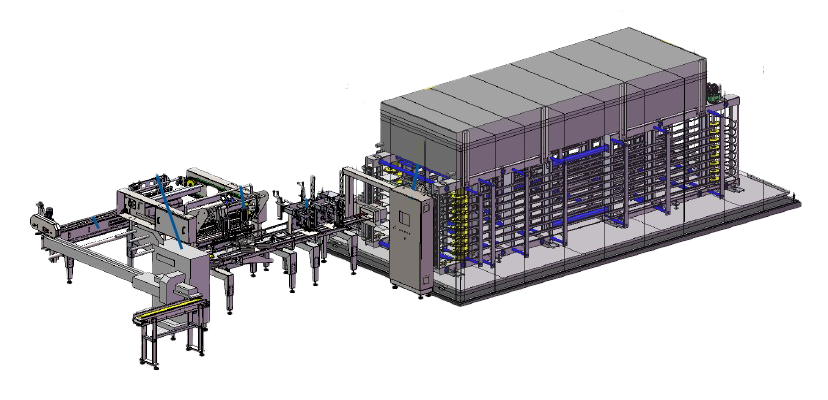

Medium production line composed of an insulated box completely made of stainless steel with double evaporator and mechanical tray conveyor unit, work surface with extrusion and elapsed time dosing stations, cutting and positioning of the stick, gripper picking system, flow-pack packaging unit and Freon or ammonia cooling units.

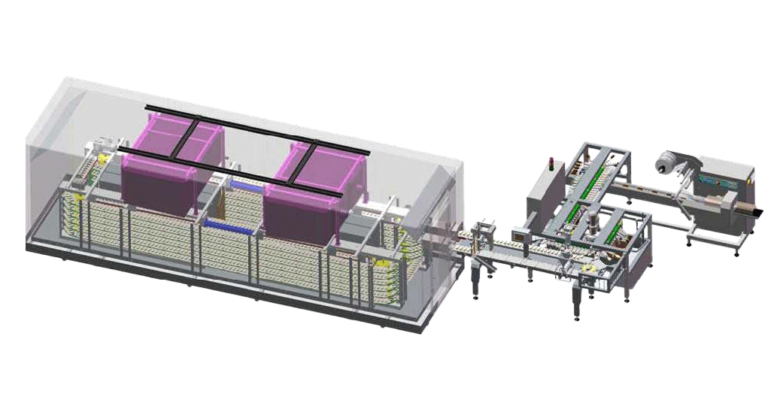

The TX8 lines are configured to extrude 2 lanes of products simultaneously, with an output of up to 18,000 pieces per hour. The large trays allow you to place 8 products per tray.

Single-lane, double-lane and multi-lane wrapping machines are available.

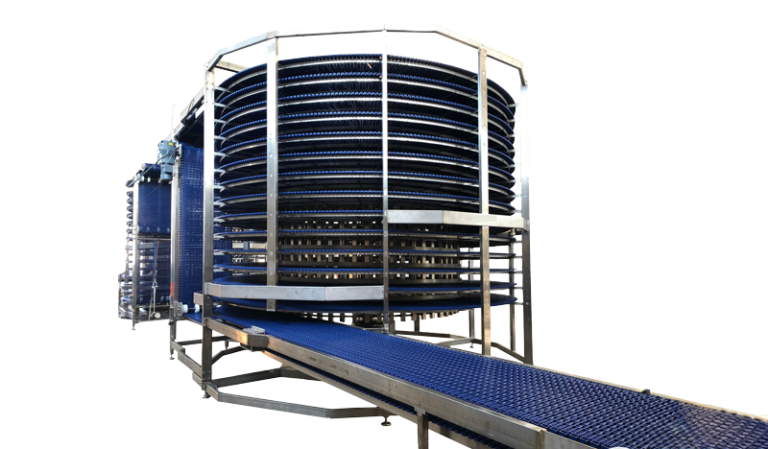

The modular system of accessories for adding and/or updating the type of product makes the line particularly versatile and suitable for all production needs and market trends:

- mini magnum

- magnum

- funny face

- ball cone

- wave

- tornado

- Sandwich

- half a sandwich

- bars

- Bon Bons