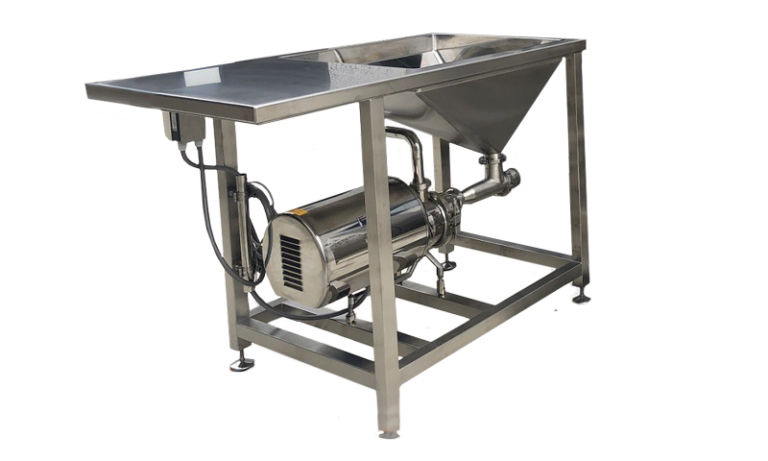

Our homogenizers are specifically designed for ice cream mixes, with abrasive characteristics and with an application range from 2 to 16% fat.

The compression head is guaranteed for 5 years against breakage, and is made from a single block of special type stainless steel. Pumping pistons with special diamond carbon coating.

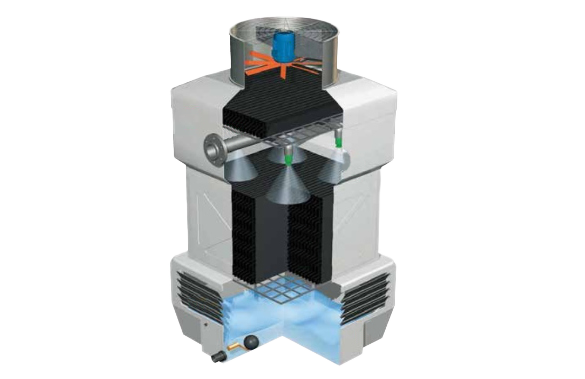

Completely interchangeable valve groups made of special material depending on the products to be treated.

Highly efficient homogenizing valves thanks to a design aimed at maximum stability/alignment of the mobile element (Shock Head) and the use of a hydraulic thrust unit designed to avoid any possible onset of vibrations during the work phase.

Sanitary safety valve, pre-loaded spring operation with interchangeable shutter and seat, working pressure 250 BAR, special versions up to 600 BAR

2 homogenization stages available flow rates from 50 liters per hour to 10,000 liters per hour