These processing line models allow energy savings of up to 75% compared to a classic batch process.

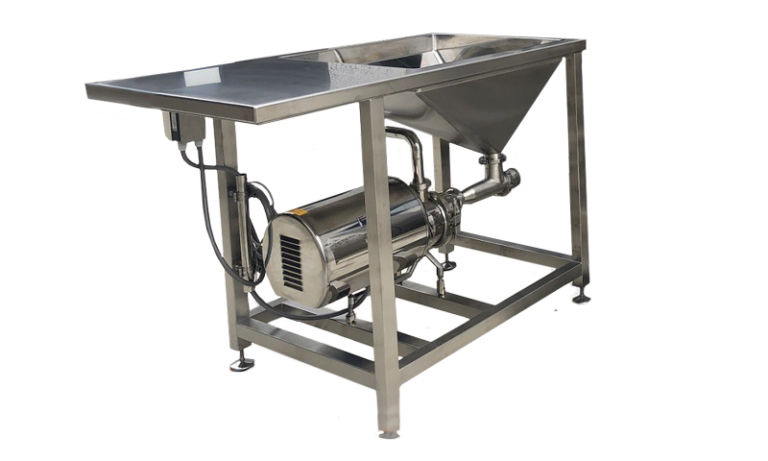

Ingredients such as fresh or powdered milk, water, vegetable fats, dairy fats, sugar, stabilizers and emulsifiers are added to the mixing tanks. The water necessary for preparing the dough is sent to the selected tank based on the quantity set on the automatic dosing system. It is also possible to automatically dose milk and cream fed from large capacity tanks.

Preheating

The heating system supplies hot water which, via the circulation pump, is sent to the water jacket of the selected mixing tank to heat the mixture up to 50°C. Once the temperature has been reached, the mixture is transferred to the compensation tank via the centrifugal pump.

Heating – recovery

From this surge tank, a second feed pump transfers the mixture to the heat exchanger in the heat recovery section. Here the unpasteurized mixture is heated to 76°C via the heat exchanger by heat transfer of the already pasteurized mixture, which is cooled in the same process by counterflow through the heat exchanger

Homogenization

Once the pre-set heating temperature is reached, the mixture is sent to the homogenizer via a centrifugal pump which, given its high pressure of 250 bar in the 1st stage and 50 bar in the second stage, reduces the fat globules into tiny particles to prevent the separation of fats and to obtain an excellent structure of the ice cream

Pasteurization and maintenance

From the homogenizer the mixture passes to the pasteurization section of the heat exchanger where it reaches a temperature of 85°C thanks to the hot water coming from the heating unit. The mixture then passes through the containment tube where it remains for 40 seconds at a constant temperature. A probe detects the temperature of the mixture and, if the temperature of the mixture is lower than the preset pasteurization level, the flow diverter valve returns it to the compensation tank to repeat the heating and homogenization cycle. If, however, it is equivalent to or higher than the preset pasteurization temperature, the pasteurized mixture passes to the cooling phase, entering the heat recovery section where it is cooled to 64°C by heat transfer provided by the non-pasteurized mixture in the heating phase. This heat recovery process allows for a significant reduction in energy requirements and is one of the advantages of an HTST type system

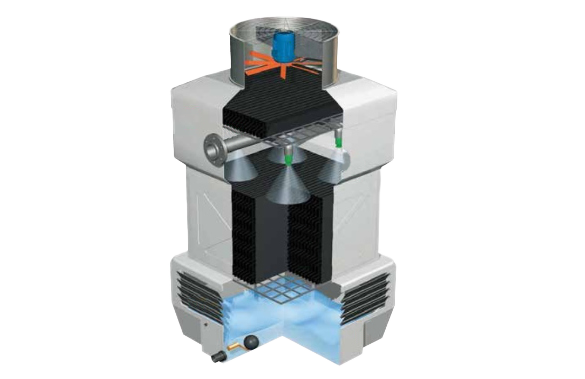

Cooling down

The mixture passes directly to the pre-cooling section of the exchanger where it is brought to 34°C using the water from the evaporative tower, and then passes to the final cooling section where it is brought to 4/6°C using ice water. The mixture is automatically sent to the maturation tanks where it must remain for 12-48 hours before being ready to use for the production of ice cream.